High

Power Wire Wound Resistors application

notes

A. Choosing Power Wire Wound

Resistors and parameters determination :

1.

Resistor power is

calculated by W=I2R

where :

W = resistor power I = maximum loading current

R = resistor rated resistance or

the maximum rheostat

resistance value

2. Never overload a power resistor

beyond the specified voltage, rated

power and current.

3. We recommend choosing a resistor

with a rated power of at least 1.3 to

4 times higher than the actual loading power if your

application requires the resistor to run continuously at full Power.

Extra safe margin power/current can extend the resistor’s service

life and lower its surface temperature.

4. If the maximum or surge power

is larger

than the rated resistor power,

please tell the actual working condition like peak/surge voltage,

resistance value, duty cycle, loading duration, repetition rate

and any cooling system around.

5. If the surge/peak voltage is larger

than the rated resistor Voltage

= SQR(P*R), please tell us the

peak-to-peak

voltage range, duty

cycle, repetition

rate per unit time or

frequency,

loading duration and any cooling system around.

6. Most of our resistors can withstand 5-10

times the rated power for 5 seconds, depending on the current pulse

width, resistor series, installation and cooling system.

7. There are no standard resistance

values for power resistor. It is better to tell

your application's working

voltage,

loading duration and

duty cycle for the Low Ohmic

Power Resistors. A different voltage can induce a very different

resistor current. Different raw materials and production processes

might need to withstand the higher

current and temperature.

For example, load current for 1 ohm and 5 ohm 10kW

power resistors

are

100A and 44A, respectively.

8. The resistor’s maximum working

voltage must obey Ohm’s Law SQR(P*R)

9. We recommend choosing Low-Inductive

Resistors for frequency

sensitive applications.

10. Most of our Power Resistors can

be manufactured according to customers’ applications like

resistance,

rated power,

resistor size,

mounting fixture and

inductive / low

inductive, pulse

voltage condition, etc.

11. Do not touch the

resistor after

connecting to a power source due to the

high surface

temperature and the chance of getting

ELECTRIC SHOCK.

12. The salty, dusty and corrosive

environment can affect the power resistors performance.

B. Other

application notes:

1. The

resistor surface temperature can reach as high as 100°C to 500°C while at full

load, depending on resistor

series, power

rating,

resistance value, working conditions, ambient temperature

and cooling system design, etc.

In general, keeping the

resistor surface temperature below

150°C to 250°C, depending on the above

factors, can extend the resistor service life

and stabilize the resistance value.

2.

Adding a cooling system such as external forced cooling fans can

lower resistor surface temperature. Do not cover the resistors!

3. Use guards and warning

labels where necessary for the power

resistors.

4. We recommend keeping all

temperature-sensitive components away from the resistor.

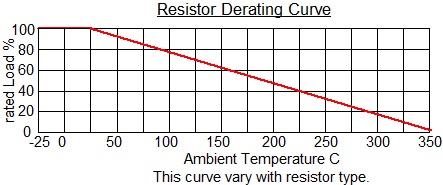

5. Below is one of the Derating Curves

for power resistors in general. Please

contact us for an individual

resistor’s derating curve.

6.

Always clean the resistor

tab terminals before

connection. Do not

clean resistor surface with organic solvents.

7. Do not scratch the resistor surface with

any hard or pointed object.

8. DDR-F and

DQR-F series power

resistors coat

with UL 94V-0 silicone coating. The resistors should be installed

away from any flammable materials.

9. Silicone coated resistors might emit smoke

during initial power loading. It is a normal phenomenon. After

loading at 100% for 1-2 hours, the smoke emission will stop.

10. The ASZ, AHR and HER resistor

external metal enclosure can be a source of interference for most

sensitive circuits. Grounding the resistor metal housing can solve

the concern.

11. All our load banks RB3A, RLB3A, RB, DB, RBA, DSR-WB, DSR3-WB, FVRB,

and RBC series should be Ground connected below connecting

to the

load source.

.

C. Adjustable Wire Wound

Resistors

DSR-F / Rheostats

FVR / Rheostat Boxes

FVRB

and

DSR-WB series application notes :

1.

Rheostat and Adjustable Wire Wound Resistor

are a type of

wire wound resistors.

2.

From a material perspective, the

allowable current depends on Ohm’s Law and the resistance

wire’s current carrying capacity, whenever the lower one.

Loading beyond this current range can damage the rheostat.

3.

The function of a rheostat is to adjust the circuit current

between the maximum current at the minimum resistance and

the minimum current at the rated resistance.

Ci.

Rheostat parameters determination

:

1.

Rheostat rated Power =

(rheostat maximum load Current)2 x rated Resistance

2. The

current of an existing application determines the maximum

load current before the adjustable power resistor or

rheostat is inserted. This consideration is for circuit

current adjustment – a rheostat in series with a fixed

resistor ( the equivalent circuit).

3.

The maximum current for two rheostats with the same rated

power can be very different.

For example, load current for 1 ohm and 5 ohms 10kW

power rheostats

are 100A and 44A,

respectively.

There are no standard resistance values for

power rheostats.

4.

The rheostat minimum

resistance value

can be calculated using the maximum current and voltage.

5.

The rheostat maximum

resistance value

can be calculated using the minimum acceptable current and

the voltage.

6.

The rheostat workable

power needs to decrease as the resistance is

adjusted towards its minimum value.

The workable power at the adjusted resistance is about the

ratio of (adjusted resistance) to (the

rheostat rated

resistance) x ( rated rheostat power) or

i.e. from the material viewpoint : power per

unit resistance

Cii.

Other

rheostat application

notes :

1.

Load current at

any adjusted resistance value

=< rheostat

rated current

Rheostat is a type of wire

wound resistor, in which the resistance wire can act

similarly to a current fuse. If the loading current exceeds

the rheostat's rated current, regardless of the load power,

the resistance wire will be burn out.

2.

Load power at

any adjusted resistance value =<

rheostat

rated power

3.

Rated

resistance value is not the same as an adjusted resistance

value.

4. The

voltage across a rheostat might need to decrease to avoid overcurrent

when adjusting the

resistance value towards its minimum value.

5.

A fixed power resistor can be connected in series with the

rheostat to protect it from overcurrent damage.

The

rheostat rated resistance =

rheostat power / (maximum

load current)2

The rheostat power = (maximum load

current)2

x rated resistance.

6.

The main role of Adjustable

Power Wire Wound Resistor DSR-F, Rheostat FVR, Rheostat Box

FVRB and DSR-WB is

to decrease, not increase, the electrical current in the

circuit.

7.

Rheostat is for

"continuous

load current"

adjustment

- nearly "continuous

resistance" range

design.

8.

For some situations, we may suggest RBA series

adjustable load

bank.

The load power / current adjustment by preset steps /

switches / circuit breakers – discrete resistance values.

With different ON/OFF combinations, a different load current

can be achieved.

Ciii.

Other rheostat application

notes :

1.

Resistance adjustment is achieved by sliding the metal

brusher across the metal resistance material.

There is a chance of flashover between two metal parts when

the resistance is being adjusted, especially at high

voltage, current and/or power conditions.

It is better to power OFF the load source across the

rheostat before adjusting the resistance values.

2. Do not

touch the adjustable

resistor / rheostat

after

connecting to the power source due to

high surface

temperature and avoid

ELECTRIC

SHOCK.

3.

We recommend choosing a rheostat with a rated

current of at

least 1.3 times higher than the circuit maximum

current if

any application requires the rheostat to run continuously at

the full power.

An extra safe margin power/current can extend

the rheostat’s service life and lower its surface

temperature.

4.

Due to high power application and rheostat consists of metal

movable parts within the rheostat,

we suggest installing the rheostat on a fixed and level

bench to avoid vibration.

5.

The salty,

dusty, humid, high temperature, vibration

and corrosive environment can affect the

rheostat performance.

6.

Both sections A and B

are

valid for the

rheostats.

Cvi.

Rheostat Bank FVRB /

Adjustable Load Bank DSR-WB

options :

1.

Meter

: Ammeter, Voltmeter, Wattmeter,

Ohm meter and Temperature meter

2. OverCurrent

protection

3.

Thermal

protection

4.

Cooling Fans

system